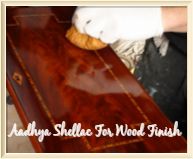

Wood finishing refers to the

process of refining or protecting a wooden surface, especially in the

production of furniture where typically it represents between 5 and 30% of

manufacturing costs.

Finishing is the final step of

the manufacturing process that gives wood surfaces desirable characteristics,

including enhanced appearance and increased resistance to moisture and other

environmental agents. Finishing can also make wood easier to clean and

influence other wood properties, In addition, finishing provides a way of

giving low-value woods the appearance of ones that are expensive and difficult

to obtain.

|

Appearance |

Protection

|

Durability

|

Safety

|

Ease

of Application

|

Reversibility

|

Rubbing

Qualities

|

||

|

From

virtually clear (super blond) to a rich orange (garnet)

|

Fair

against water, poor solvent protection

|

Durable

|

Safe

when solvent evaporates, used as food and pill coating

|

Clogs

spray equipment. Quick solvent flash time makes brushing difficult. Ox or

badger/skunk hair brush recommended. Easy to pad, however French Polish is

difficult

|

Completely

reversible using alcohol

|

Excellent

|

||